Wire probe characteristics

The wire probe is a probe that does special plating and insulating coatings to ultra fine wires such as tungsten. It is a probe using vertical contact deflection of ultra fine tungsten wire, as contact force.

PROBE

The wire probe is a probe that does special plating and insulating coatings to ultra fine wires such as tungsten. It is a probe using vertical contact deflection of ultra fine tungsten wire, as contact force.

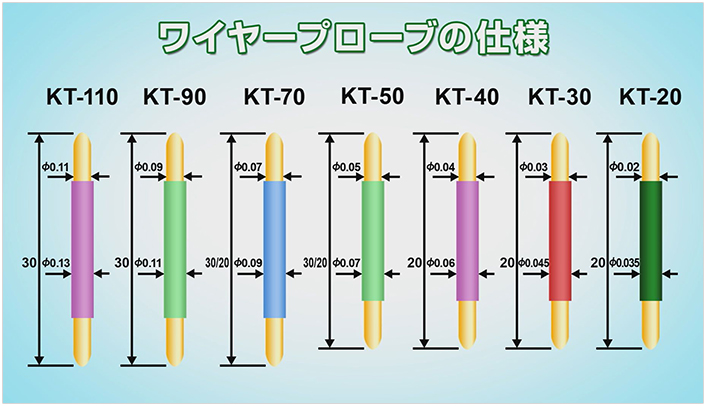

| Type | KT110-30 | KT90-30 | KT70-30 | KT70-20 | KT50-20 | KT40-20 | KT30-20 | KT20-20 |

|---|---|---|---|---|---|---|---|---|

| Min pitch | 300μm | 150μm | 100μm | 100μm | 80μm | 65μm | 55μm | 45μm |

| Contact force | 20.0g | 8.0g | 3.0g | 8.0g | 2.0g | 1.5g | 0.8g | 0.5g |

| Allowable current | 1100mA | 750mA | 500mA | 500mA | 250mA | 200mA | 150mA | 100mA |

| Individual resistance | 200mΩ | 450mΩ | 620mΩ | 430mΩ | 680mΩ | 900mΩ | 2300mΩ | 4820mΩ |

| Diameter | Φ110μm | Φ90μm | Φ70μm | Φ70μm | Φ50μm | Φ42μm | Φ32μm | Φ22μm |

| Standard stroke | 250μm | 250μm | 250μm | 250μm | 200μm | 150μm | 100μm | 100μm |

| Self inductance | 36.0nH | 37.2nH | 38.7nH | 24.2nH | 25.5nH | 26.4nH | 27.0nH | 28.8nH |

| Capacitance | 0.41pF | 0.21pF | 0.15pF | 0.10pF | 0.12pF | 0.13pF | 0.14pF | 0.13pF |

Each size probe has three probe tip shapes like round, needle and flat. The optimum shape can be selected depend on the characteristics of the DUT and the testing purpose.

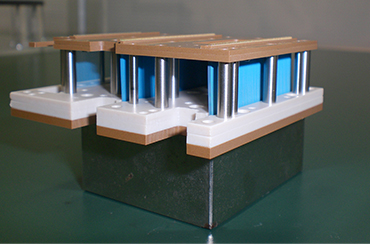

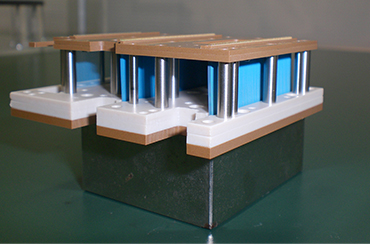

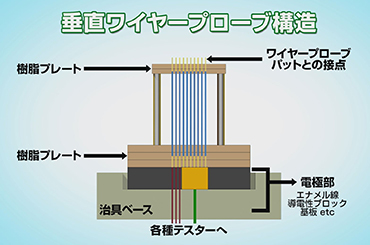

The fixture structure using wire probe is really simple.The universal part assembled by combining multiple plates made of resin or ceramics which made precise holes in testing position, and posts. Insert the wire probe into the hole on one side of the universal part so that the tip side contacts the DUT.On the back side of the probe, make an electrode part by a plate embedded with enameled wires and conductive blocks.We will ship after finishing the conection processing of electrode wiring, so you can connect to any tester or inspection equipment.

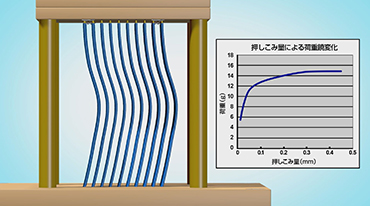

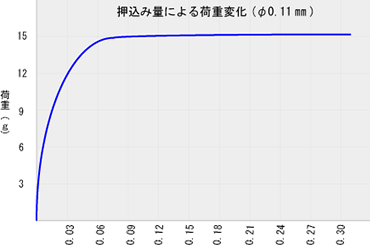

This structure which used contact deflection between the two plates is not only makes the structure itself simple but also makes a uniform contact force.With this wire probe test fixture, it is possible to generate the maximum force of the probe by just overdriving 50 μm.Because of these characteristics, The same force can be applied to all probes even if the surface of DUT is slightly distorted. Therefore, the same contact force will be applied, which reduce the scratches in the test.

This structure is very easy to maintain. Because of the universal part can be removed from the electrode part with a simple tool and the operator can replace the pins easily in clean room.

If you have any question,please feel free to ask.